Hyde Sails International 14 Technical Review

by Mike Lennon, Hyde Sails 10 Dec 2004 17:03 GMT

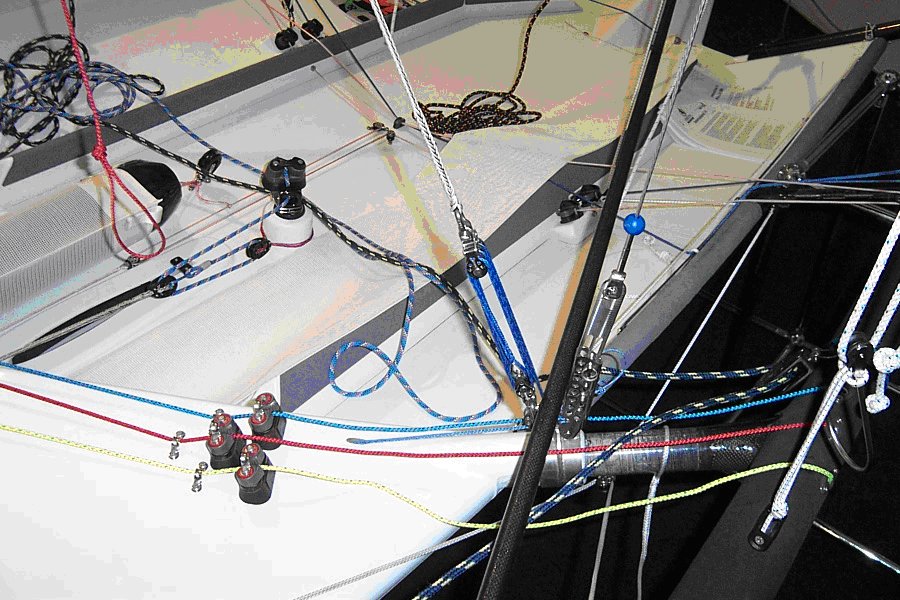

Ovington Bieker 4 © Hyde Sails

As a sail maker it is very easy to become bogged down in the detail of sail design and overlook the sum of the parts. These being all the parts that go into the boat as a whole and the way they all interact.

The most fundamental choice and biggest investment of course is the choice of hull - if you are Flush there seems to be 3 choices from new; - The oldest and most proven being the Ovington Bieker 4. This design has won most things of any importance and remains the benchmark design. It’s very well built and relatively easy to sail. Fit outs vary to customer preference but the standard is to have a moderate amount of racing adjustability.

In the hands of Andy Fitzgerald, James Fawcett and others, the Ovi B4 proved to be the 2004 benchmark design.

Developed over the winter of 03/04 the Morrison 12 by RMW was a fairly radical departure from the Bieker style. Beautifully presented, the first production boats hit the water in March with much anticipation. Whilst the boat managed in its first season to pick up much of the major silver ware including POW and the Europeans, the boat has proved tricky to sail in big waves and strong winds – its narrow sections make it very dependant on rudder trim. Undoubtedly fast but whether it’s any faster than the B4 remains to be proved. The standard fit out from RMW is very basic with the emphasis being on mast tweaking to get the last ounce of performance.

The Bieker 5 debuted in the UK at POW this Year with its builder Chris Turner – the hull was rushed out to meet the schedule of the nationals and consequently far from production looking in presentation. Chris showed great promise but in a week of fickle breeze, not much was learned by anyone regarding hull shape at this regatta.

Its next outing was in the hands of James Fawcett at the Europeans, finishing 3rd behind reigning world champion Rob Greenhalgh in his M12 and Chips Howarth in a non Ovington B4. Whilst the result doesn’t show a significant jump in pace all the talk on the shore and in the bar was that the few B5’s at the event where fast but not consistent, due to lack of time on the water.

To add to the intrigue, the story goes that an unnamed UK based sailor is funding the development and tooling of the B5 in the UK, exclusively for his own use for a period of time taking in the 2005 worlds – now that’s chequebook sailing? All he needs now is his own sail maker!

Rigs:

CST, Bieker and Seldon are the main players, CST and Bieker being the most prolific. The CST comes in many varieties. It was the CST in the hands of Andy Fitzgerald proving very constant across the wind range that set the benchmark. One difference in set up from the standard CST was Andy lead his uppers through the lower spreaders in traditional 14 style where as most CST‘ers lead them directly down to the main shroud chain plate. Through the lower spreader to the mast base, makes set up more user friendly and readily changeable. As the tip bends to leeward the mid mast is held to some degree side ways but encouraged to bend fore and aft by the load in the windward upper shroud. This opens the mid leech without allowing a dramatic change in entry and exit angle, which occurs when the mid mast bends to windward.

The Bieker rig looks stiff in its current form compared to others but again has had good results but has appeared inconsistent.

The Seldon rig is the only shaped rig in the fleet its aerofoil section looks quite big in comparison to the round masts, but when measured it’s narrower on the side and longer fore and aft. The theory goes that this shape, whilst bigger, encourages the airflow to attach to the lee side more quickly, reducing drag and increasing the forces acting in the front part of the sail.

There is nothing new here and the argument is well proven – the move to round sections was simply due to what was available in carbon. Seldon have worked quite hard at getting a user-friendly robust section – they are also fitting adjustable spreaders as standard. Whilst this allows important fine-tuning it has also proved a weak point, as metal rivets and carbon are an accident waiting to happen. With both Mike Lennon’s and Chips Howarth’s rigs failing from the rivets working out of the carbon. Lennon’s rig is being fitted with adjustable carbon spreaders bonded to the mast for the 2005 worlds.

The correct combination of Glass and Carbon is the key to top mast development – too much glass is heavy but robust and lacking fast response, too much carbon is lighter but fragile and will not take high bending without failure.

String rigging has yet to catch on, some use Vectran jib halyard/fore stays, but that’s about it on the standing rigging. In theory both Vectran and PBO offer weight savings with similar diameters and strength to the current wire used. It will come; it’s just a question of when.

Foils:

Morrison rules in the UK fleet with all the RMW and most of the Bieker fleet using his design of centre board – interestingly the RMW centre board is thinner in section but much heavier than the Turner built version, outline profiles are very similar.

The foiled rudder is where we see a big difference in philosophy. The Bieker system has a fixed blade with a spring-loaded rod pushing against another rod, which is controlled in the boat via a control line. The horizontal foil moves, the rudder doesn’t.

The RMW system has fixed horizontal foils bonded to the rudder with the whole rudder pivoting fore and aft. This is a cheaper system and should allow for a slightly lighter set up, the major down side is it makes the boat heavy to steer when the foil is set to max aft – it’s just like pivoting your rudder back in any boat whilst going down wing in force 6 with a 30 square meter spinnaker up.

The move this year is to longer and thinner horizontal foils – the latest Bieker design being 1.2 meters from tip to tip. But whilst this is good upwind in planing conditions (you can use less angle to the same effect) you still have to go down wind and tow them around in the light, where they do little. As a 14 goes downwind at approximately twice the speed it goes upwind – this should in theory mean the foil should be 4 times smaller to be optimised for down wind work.

Sails:

Fuller sails on more flexible rigs – that’s how we see things, working with the Seldon rig we have developed a very powerful set up that can be de powered through heavy use of Cunningham and mast rake.

The flexible robust tip allows huge amounts of bend, allowing us to build deeper sails we know we can blade off when necessary.

Our choice of cloth reflects a philosophy of trying to cover all the angles – it’s easy to estimate the primary load directions on most sails, the secondary ones are not so easy, and as we change the chord depth, whether automatically through increased twist via tip reaction, or by pulling something, all the load directions alter.

To solve this and give us a self-adjusting sail (sounds like rubbish I know, but) what we are talking about is angling the cloth or choosing a cloth that won’t allow the localised shape change. So as the sail loads up it doesn’t get deeper. If we used a unidirectional material and the fibres in the leech direction only, as the loads increase the leech will move the least whilst all the other significant load directions will stretch. This makes the draft move aft and the depth go up. If we angle the fibres to go parallel to the middle of the sail it would hit the leech off line giving no support so the sail would flatten as the loads increase.

We need to choose a cloth with loads of fibre running in several directions or go for a high film content to cover every angle.

We chose C581 black – An Aramid yarn by Teijin of Japan laminated by Dimension Polyant in 3mm film.

The full radial construction means we angle the cloth to cover all primary and most secondary loads and allow the Technora Aramid Xply yarn combined with the 3 mm film to cover all the lesser loads. This means the sail behaves in a very balanced manner – we have the balance between needing the large roach to stand and be powerful, whilst being low stretch away from the leech, to stop the draft moving to leeward and aft. Effectively as the leech twists open the sail gets flatter automatically i.e. Self-adjusting.

Our Jib is quite full in the base and moderate in the middle and top, with the draft well forward. This means we sheet quite firmly both along the foot and down the leech. So we can point high – the down side can be footing, as you ease the sheet the twist is desirable but the extra depth low down is not. But by allowing the jib lead to go to leeward rather than over easing solves this problem. Allowing more rake also opens the leech without deepening the foot.

Spinnakers:

The use of 6611polyester, coated in silicon means we have a half-ounce kite right to the moment you leave the cover on and tie the boat firmly to the ground.

It’s more expensive than nylon, but harder wearing when coated in silicon (a disaster when not). We find this cloth is easier to launch and recover and lasts longer.

Our design is now much longer on the luff and has a more projected luff; it’s also a little deeper than previous designs and bigger.

The 3-recovery patch system allows for shorter socks giving a tan to the lower leg! But this is optional!

More Information: